In the context of plastic recycling and waste management, industrial plastic crusher is instrumental in promoting a circular economy and mitigating environmental impact. Here are 5 key features of industrial plastic crusher that significantly enhance recycling efficiency:

High Throughput Capacity:One of the most critical features of an industrial plastic crusher is the ability to process large volumes of plastic waste quickly. High throughput capacity ensures that recycling operations can keep pace with the generation of plastic waste, minimizing storage requirements and maximizing recycling throughput, which is especially valuable for facilities dealing with high volumes of waste plastic film.

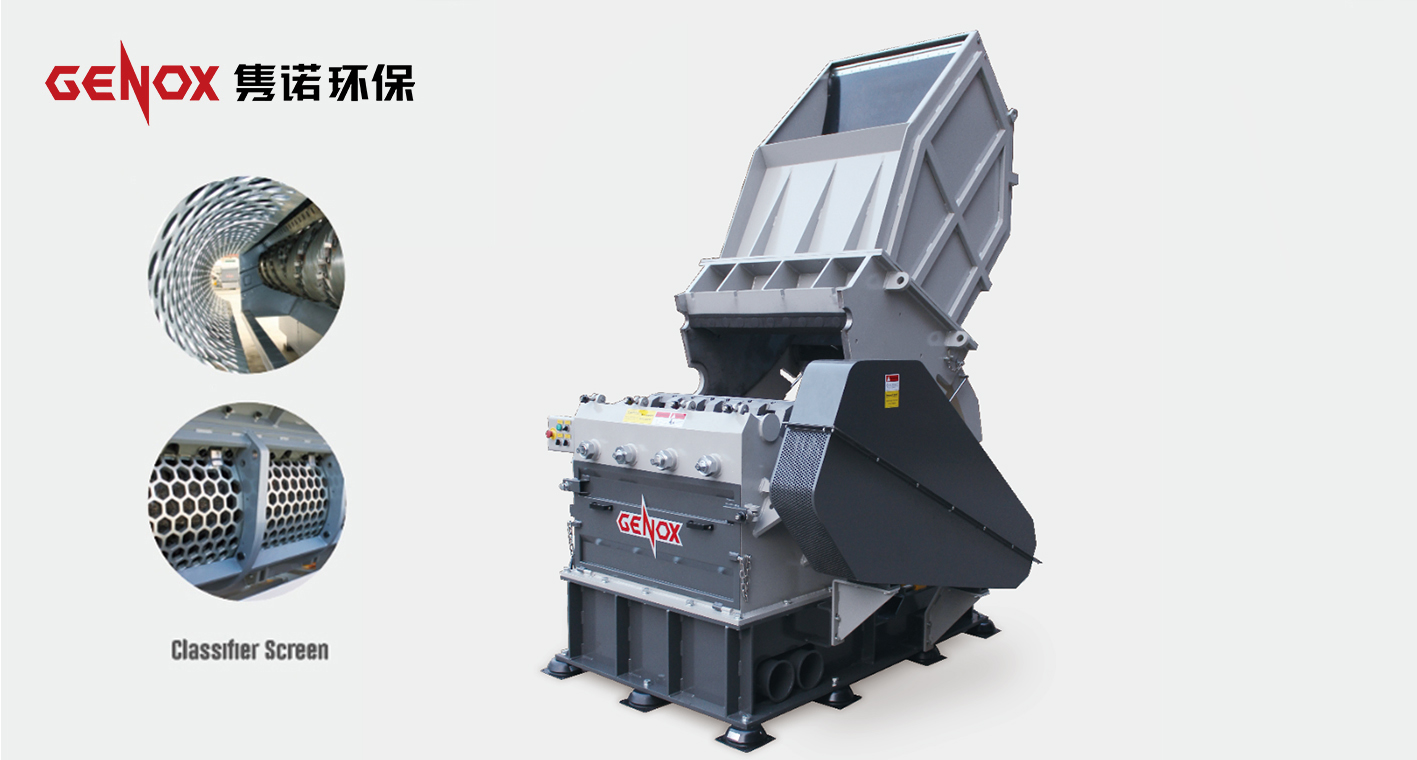

Customizable Output Size:Customizable screen or gap settings allow customization of the crushed plastic particle size, which is crucial for downstream processing. Smaller particle sizes can improve the efficiency of subsequent processes like extrusion, granulation, or even direct reuse in some applications. It also facilitates sorting and separation of mixed plastic types, enhancing the overall quality and value of the recycled material.

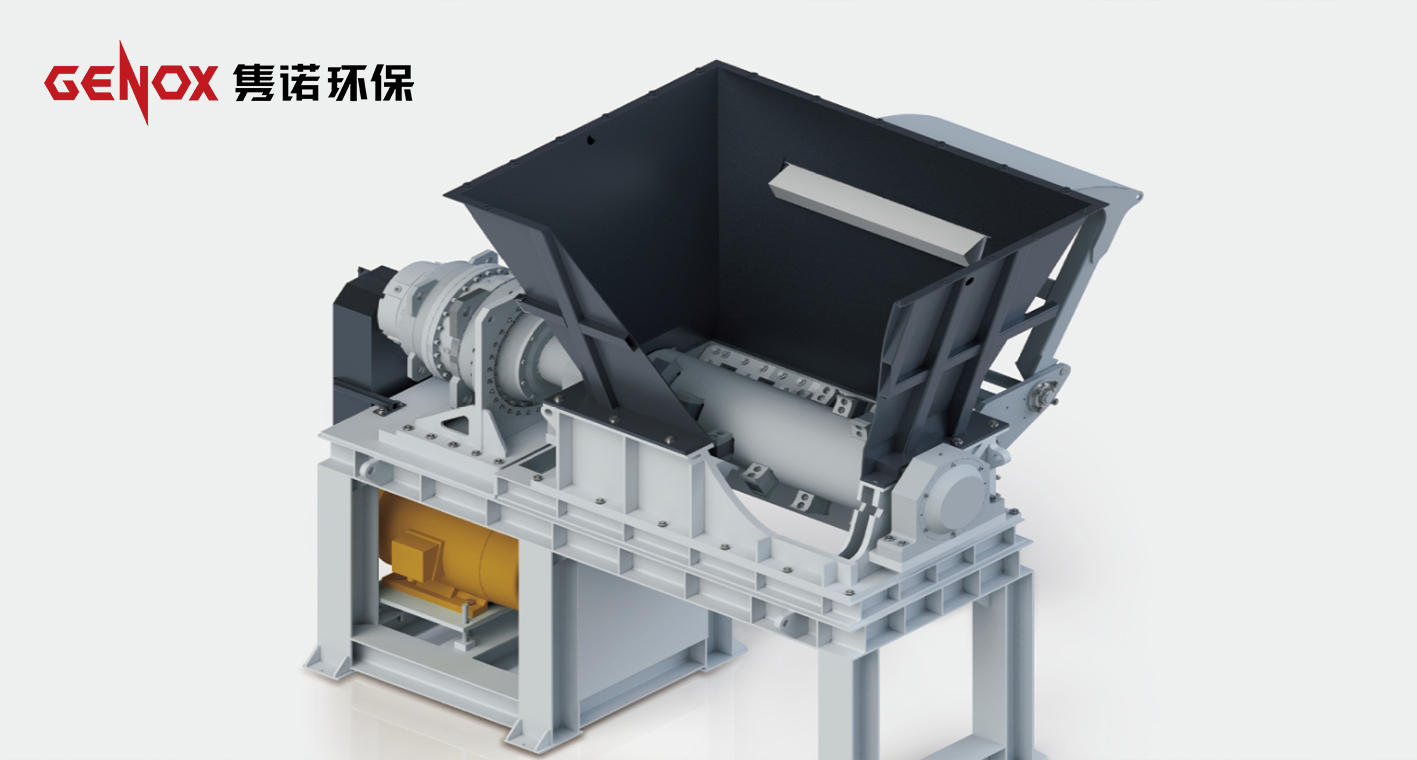

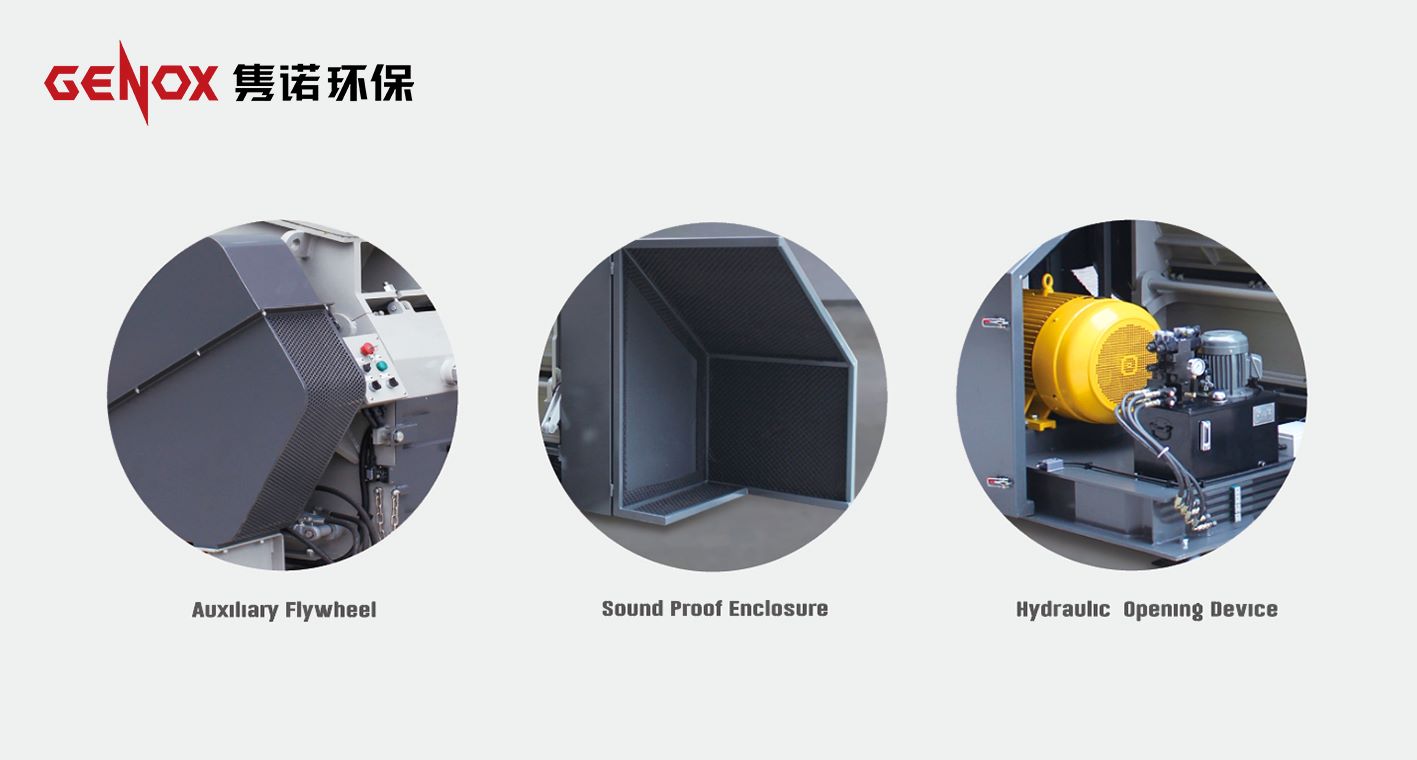

Durability and Longevity:Durable construction and high-quality bearings, pulleys, and cutting edges ensure minimal downtime for maintenance and repairs, maximizing operational uptime and productivity.

Energy Efficiency:The industrial plastic crusher adopts advanced motors and belt transmission devices, which can significantly reduce energy consumption during operation. This not only helps to reduce production costs, but also reduces the burden on the environment. Meanwhile, through reasonable sealing and sound-proof design, the crusher will not produce secondary pollution during the crushing process, ensuring a clean and quiet working environment.

Easy Maintenance and Cleaning:To maintain peak performance, industrial plastic crusher must be regularly cleaned and serviced. Machines designed with easy access to critical components, removable screens, and streamlined maintenance procedures facilitate quick and efficient cleaning and maintenance tasks. This not only reduces downtime but also ensures the crusher remains in optimal working condition, maximizing recycling efficiency over its entire lifespan.

By incorporating these key features, industrial plastic crusher significantly contributes to the circular economy by facilitating the efficient conversion of waste into valuable resources. It help reduce landfilling, minimize environmental pollution, and create economic opportunities through the reuse and recycling of plastic materials.