Lithium is a highly reactive chemical element, and shredding it may pose a risk of fire or explosion. Ensuring safety and efficiency is crucial during the process of battery shredding. Therefore, the industry-leading GENOX Twin Shaft Shredder and automated battery recycling solution are recommended.

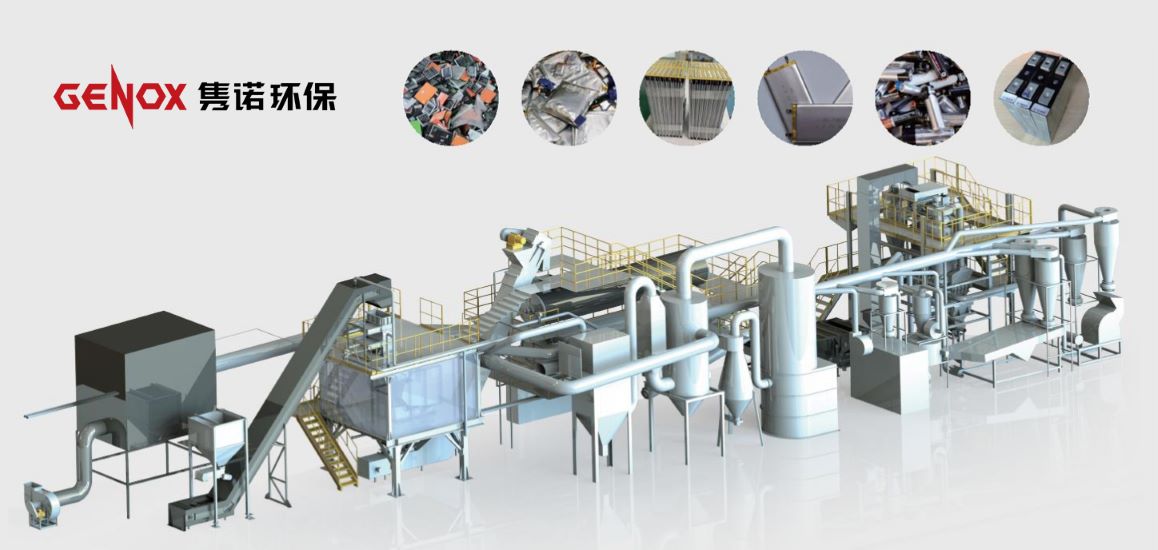

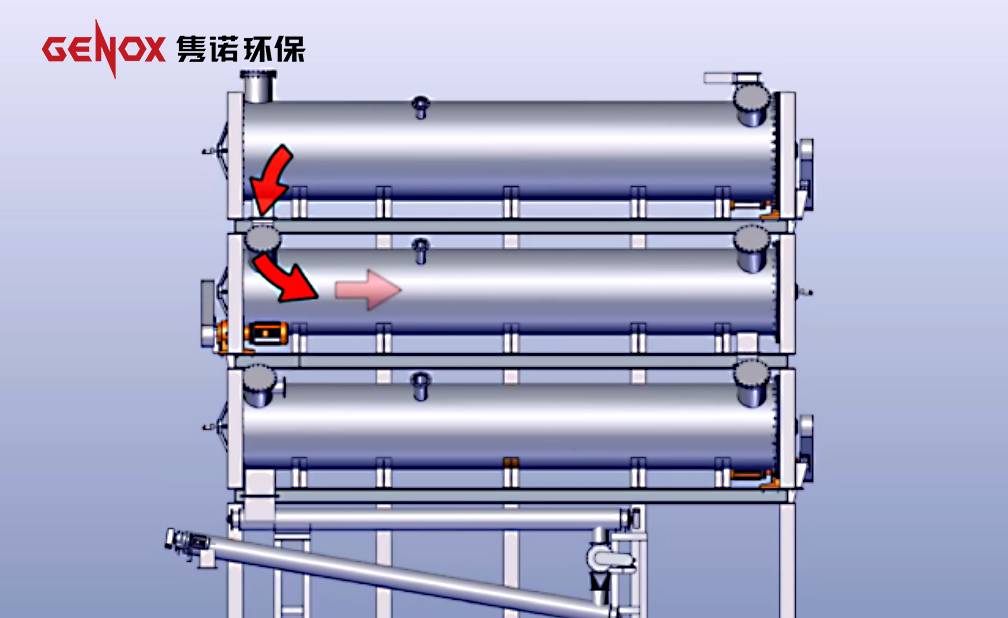

In order to ensure safe production, block valves are mounted on the discharge of the shredder to stop back flow of the gas. Besides, separation by vibration and air is applied to remove heavy impurity material of battery casing and release blackmass for recovery. At the same time, automatic control system with oxygen control, temperature control, camera surveillance, PLC and host computer is used to ensure the safety.

In order to improve the production efficiency, the heavy-duty twin shaft shredder is used for rapid shredding without energy releasing. Furthermore, this twin shaft shredder + crusher solution can handle most batteries on the market. Solvent material are dried and collected by heating process, plastic material and battery separator can be collected according to requirement. In addition, the high-efficiency magnetic separation module, dry stripping device, copper and aluminum comprehensive sorting device and airflow sorting device can accurately sort various materials.

For more information, please view the following video.

Lithium ion Battery Recycling System / Battery Recycling System - Genox (youtube.com)