With 1.5 billion end-of-life tires discarded globally each year, sustainable recycling has become a pressing imperative. Traditional disposal methods contribute to landfill overflow and pollution, making tire shredding an essential process for sustainable waste management. Through full-chain technology incorporating intelligent tire shredding, efficient sorting, and resource regeneration, these once-massive piles of "black pollution" are now transformed into valuable assets in the circular economy. This article explores the importance of tire shredding, its benefits, and its applications in various industries.

Tire shredding is a mechanical process that converts end-of-life tires into smaller pieces, making them easier to handle, recycle, and repurpose. Because tires are designed to be durable, they require specialized shredding equipment to effectively break down their reinforced rubber and steel structure.

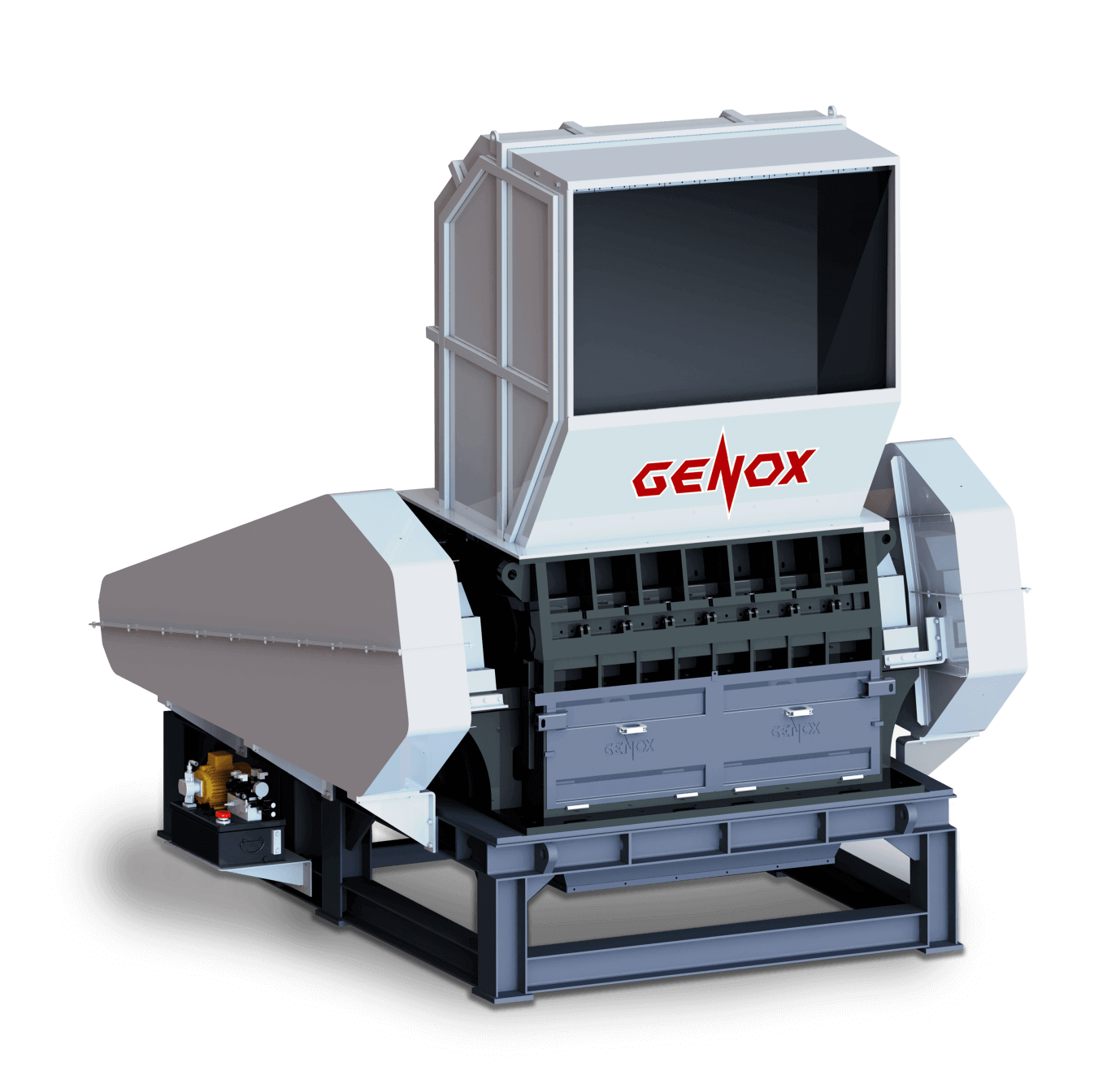

There are different types of tire shredders, each designed for specific recycling needs:

Primary Shredders – Reduce whole tires into large rubber chunks for further processing.

Secondary Shredders – Produce finer, more uniform rubber pieces suitable for repurposing.

Wire Separator S Series

Granulators – Further refine rubber into fine granules or powder used in advanced manufacturing.

Reduces landfill waste – Shredding tires prevents excessive accumulation in landfills and minimizes toxic emissions.

Prevents fire hazards – Whole tires pose combustion risks, while shredded tires are safer to store and transport.

Supports circular economy – Reclaimed materials from tires contribute to sustainable production.

Cost-effective waste management – Reduces disposal and transportation costs.

Material recovery – Enables the extraction of rubber, steel, and textiles for reuse.

Alternative energy source – Shredded tires can be used as Tire-Derived Fuel (TDF) in cement kilns and power plants, offering an eco-friendly energy option.

Taking Genox's tire recycling system as an example, its innovative technology maximizes the reuse of rubber, steel, and textile fiber from waste tires. The tire shredding process involves the following key steps:

Whole tires enter the primary shredder, where they are cut into manageable pieces. The bolted cutting blade system reduces operational costs and simplifies maintenance.

The two-stage rasper system effectively extracts steel wires from the rubber, ensuring effective separation and the production of clean wire.

Rubber particles are further processed in a fine granulation system, featuring a special rotor designed specifically for tire rubber size reduction. This ensures maximum throughput while minimizing excessive fines. It is also optimized for low operational and wear costs.

Textile and dust are aspirated at multiple points, with a central reverse jet filtration system extracting dust across the entire shredding system, ensuring a clean and efficient operation.

Automated systems link component actions to maximize system capacity while protecting against interfering materials, improving both efficiency and reliability.

Learn more about how our Tire Recycling System works.

Tire shredding is a key solution for reducing waste and supporting sustainable recycling. By converting discarded tires into valuable materials, businesses and municipalities can lower their environmental impact while unlocking new economic opportunities. Advanced tire shredding machines optimize material recovery and efficiency. Discover more about their innovative features in our detailed analysis: 10 Insights into Our Tire Shredding Machines.

The demand for responsible waste management solutions continues to rise, making tire shredding an essential practice for modern recycling. Whether for energy production, construction, or manufacturing, repurposed tires contribute to a more sustainable future. Choosing advanced tire shredding technology ensures high efficiency, optimized resource recovery, and environmental benefits.