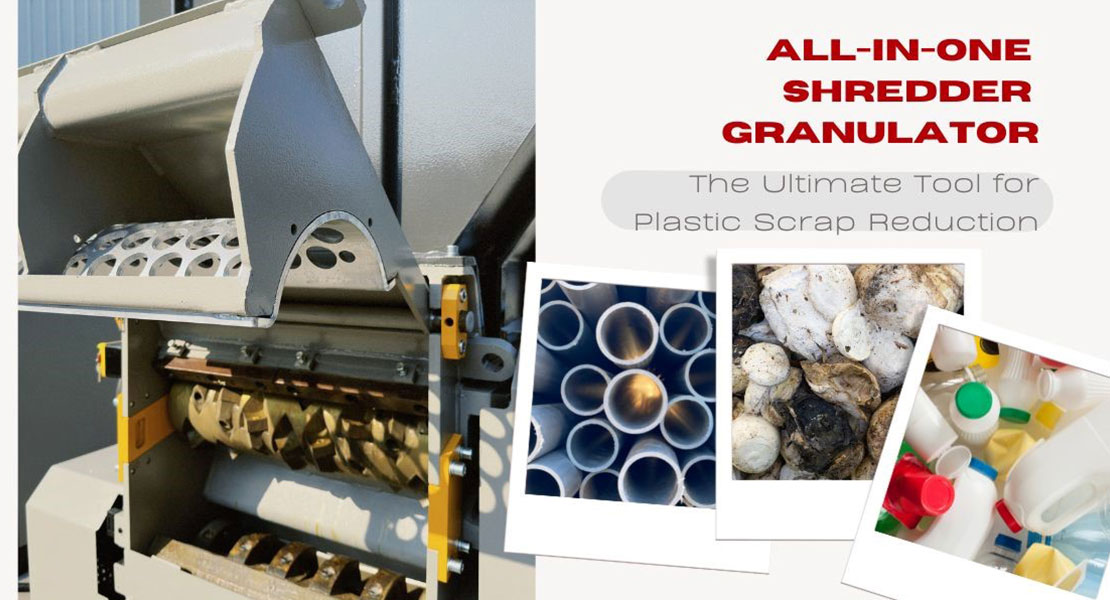

When it comes to reducing plastic waste, traditional plastic shredder and granulator lines are a well-established solution. However, investing in these systems can be costly, and they also take up considerable space. This makes it challenging for smaller businesses or those with limited resources to take advantage of these systems. To address these issues, the all-in-one plastic shredder and granulator machine was developed. This innovative technology provides an affordable and space-saving option for reducing plastic waste. In this article, we'll explore the features and benefits of the shredder and granulator combo and its successful implementation in various industries.

Compared to a stand-alone plastic shredder or plastic granulator line that includes a conveyor belt, shredder, crusher, and aggregate system, the shredder and granulator combo simplifies the entire process into a single integrated machine. This makes it much easier for operators to manage the shredding and granulating process, reducing the need for additional equipment and labor.

This advanced equipment is designed to shred plastic materials into small pieces and then granulate them into uniformly sized plastic pellets that are more manageable and easy to transport. By adopting this dual-purpose machine, various benefits can be realized when compared to traditional plastic reprocessing methods. For instance, the equipment is more compact, easier to maintain, and incurs significantly lower investment costs. Moreover, the cost of wear parts is significantly reduced, and energy consumption can be cut by up to 7%.

But, how does this shredder and granulator combo machine function? The equipment has a unique design with a shredding area located at the top. It features a small-blade-rotor-shaft arrangement with a forced feeding mechanism to ensure efficient shredding. The crushing area is located below, and the rotor shaft and feeding mode can be adjusted based on the characteristics and output of the materials being crushed. The machine first shreds plastic waste into smaller fragments, which are then granulated into uniformly sized plastic pellets. The pellets can be stored for use in producing new plastic products, thereby closing the loop of minimizing plastic waste and promoting sustainable practices.

One significant advantage of this equipment is that it eliminates the need for conveying equipment, as the shredded and crushed materials can be easily collected. Furthermore, the machine has a compact design that requires less floor space, making it a cost-effective option for businesses.

The shredder and granulator combo machine is an increasingly popular solution for plastic recycling and reprocessing due to its efficiency and practicality. This advanced equipment boasts several key features that make it a reliable and cost-effective option :

The machine's closely arranged small-blade-rotor-shaft structure and forced feeding mechanism allow for efficient shredding of plastic scraps and wastes, including tough-to-process materials. It can handle a wide variety of plastic materials, such as PET, PP, PS, and vinyl, in various forms, including lumps, post-consumer products, and post-industrial refuse. The machine can also shred other scrap materials, such as soft metals and cables.

The machine's compact design has a small footprint, making it ideal for businesses with limited space. It can save up to 86% of space.

This combo machine combines two pieces of equipment into one, saving the cost of conveyors needed to connect them. This results in energy savings of up to 7% compared to separate shredder and granulator lines.

Compared to stand-alone shredders and granulators, this all-in-one machine integrates a conveyor belt, shredder, crusher, and aggregate system, simplifying the entire process into a single integrated machine. This means that maintenance is much easier. The machine's compact design makes it easier to maintain and results in a significant reduction in overall equipment investment costs. Additionally, wear part costs are reduced.

The shredding and granulation process ensures that all plastic waste is fully utilized, effectively reducing material waste during the plastic scrap recycling and reprocessing process.

The machine is designed to operate with minimal noise emission, making it an ideal option for businesses located in noise-sensitive areas.

The shredding and granulating system can handle a broad range of plastic sizes and shapes, ensuring that all plastic waste or scrap is fully utilized.

The shredder and granulator combo machines are widely used in the recycling industry. These machines can process a wide range of materials. The shredder is responsible for breaking down the materials into smaller pieces, while the granulator further grinds the pieces into granules that are readily recyclable. This method is essential for the recycling industry as it helps to reduce waste and promote resource conservation.

The plastic and rubber manufacturing industry heavily relies on shredder and granulator combo machines. These machines are used to process materials such as plastic rubber, lumps, plates, scrap, frames, pipes and PET bottles, and more! The shredder reduces these materials into smaller pieces, while the granulator refines them into granules that can be used to create new plastic and rubber products. This process effectively reduces the waste generated by these industries and promotes resource conservation.

There are lots of industrial sectors that can benefit from shredder and granulator combo machines. Here are 2 case studies :

A Turkish company specializing in plastic injection molding machines, recently purchased our 250KG Plastic Block Shredder and Granulator All-in-One Machine, along with a GFZ4 Fan and CL250 Wind Conveyor Hopper. This purchase has helped HASTEK PLASTIK to streamline their plastic processing operations, improving efficiency and reducing waste.

A Japanese company that is a leading provider of high-quality machinery and equipment. They recently purchased our GLC Washing Line, YS1500-Y Pre-shredder, GSF1260 Separation and Sedimentation Tank, GFW5030 Friction Washer, GCV600 All-in-One Shredder and Granulator Machine, and WP accessories. This purchase has helped SYOKEN CO.,LTD to enhance their plastic recycling capabilities and improve their environmental sustainability efforts.

Further reading: How Does Plastic Large Pipe Shredding and Recycling Promote Sustainability and Circular Economy?

Genox is a leading high-end manufacturer of solid waste recycling machinery and equipment based in China. Our product line includes plastic pipe shredders, lithium Ion battery recycling machine, fridge shredder, wide range of shredders, and we specialize in designing and manufacturing large-capacity industrial shredders to meet all your plastic pipe recycling needs. With Genox, you can get a total solution for your recycling requirements.

We invite you to explore our product page to discover how our shredder and granulator combo can benefit various industries, such as recycling, plastic and rubber manufacturing, injection molding, extrusion, and blow molding. Alternatively, you can contact us today to learn more about our solutions.

Upcoming Exhibitions:

We are excited to announce our participation in several upcoming exhibitions where we will showcase our latest recycling products. These exhibitions include Chinaplas 2023, IFAT Eurasia 2023, SMM 2023, and Equiplast 2023, Plastico Brazil 2023, among others!

| Date | Exhibitions | |

|---|---|---|

| 1 | April 17 – 20 | Chinaplas 2023 / China |

| 2 | April 27 – 30 | IFAT Eurasia 2023 / Istanbul |

| 3 | May 9 - 11 | SMM 2023 / China |

| 4 | May 30 – June 2 | Equiplast 2023 / Barcelona |

| 5 | June 1 – June 2 | 2023 Industry Green Development Conference / China |

| 6 | June 21 – June 24 | 2023 InterPlas / Thailand |

| 7 | Sept.12 - Sept. 14 | WASTE-tech / Russia |

| 8 | Sept.26 - Sept.28 | Interplas / Birmingham |

| 9 | Oct.10 - Oct.13 | Lyon Eurexpo Pollutec / France |

| 10 | Nov. 7 – Nov. 10 | PLASTIMAGEN 2023 / Mexico |

| 11 | Nov. 15 – Nov. 16 | Plastics Extrusion World Expo 2023 / USA |

As experts in manufacturing shredders and granulators, we understand the critical importance of providing an all-in-one solution for efficiently reprocessing plastic waste. Traditional methods can be challenging, especially when dealing with lumpy, chunky, bulky materials, and cork. Our shredder and granulator combo machine provides a range of benefits, including reduced material waste, low energy consumption, and user-friendly design for easy operation and maintenance.

We invite you to explore our product page to discover how our shredder and granulator combo can benefit various industries, such as recycling, plastic and rubber manufacturing, injection molding, extrusion, and blow molding. Alternatively, you can contact us today to learn more about our solutions such as Lithium-Ion Battery Recycling Machines or Plastic Pipe Shreddering and Recycling Machines.