RDF (Refuse Derived Fuel) is created from Municipal Solid Waste (MSW), which is made up of non-hazardous, residential, industrial, commercial, construction and demolition waste. RDF fuel is renewable, easy to transport and easy to store.

SRF (Solid Recovered Fuel) means solid renewable fuel produced from secondary resources with a low moisture content. SRF is a fuel produced from non-hazardous waste in compliance with the European standard EN 15359.

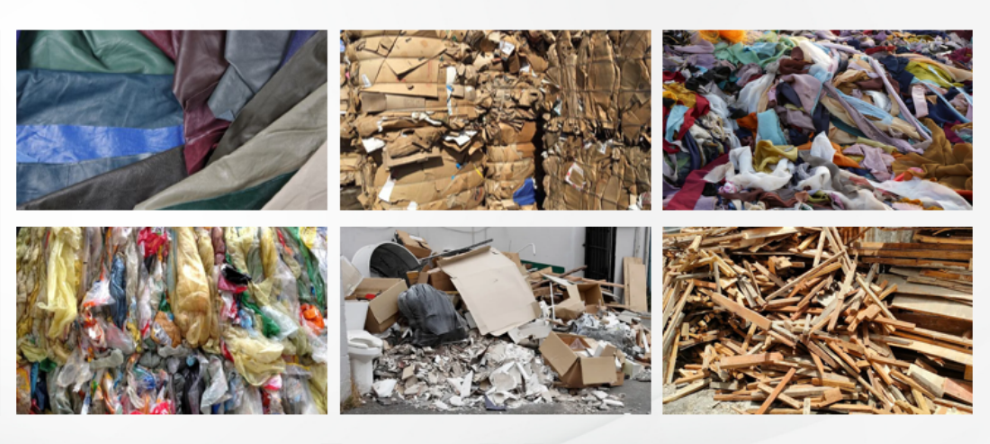

As the world looks to ease its reliance on fossil fuels, RDF and SRF are increasingly being utilised for power generation as more sustainable energy sources. Genox’s Industrial Solid Waste Recycling System can be used for the recycling and treatment of various types of waste textiles and high calorific value industrial solid waste. Then, the leftover materials are shredded and treated before being compressed into RDF/SRF, which can be incinerated and generate electricity.

The system uses heavy-duty hinge belt conveyors, which are suitable for high loading and materials impact whilst being sealed to prevent leakage of material. And it’s equipped with the Over-band Magnet, which is used to securely extract ferromagnetic parts such as scrap iron and other ferrous scrap metal. Besides, with a Trommel Screen to separate materials that have a great impact on equipment such as sediment and stone, it’s possible to extract different fractions in this process stage, such as fine particles and oversized fractions to obtain high-quality, medium-particle premium RDF/SRF. The automation ensures that the component's actions are linked, the system capacity is maximized, and the system is protected against interfering material in the best way.

Contact Genox to learn more about recycling technology.